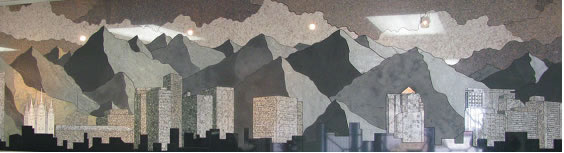

waterjet cut from slate, granite, gold, brass, and ceramic

4' x 20', 210 pieces, 1400 pounds

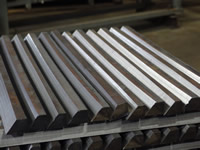

Saw Cutting

Value added processing

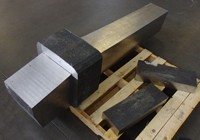

We have invested $400,000 in state-of-the-art saws that are the largest in the valley, capable of cutting virtually any material from aluminum to hastelloy at any angle. The saws equipped with horizontal, vertical, and tilt heads allow us to cut angles in more than one direction to reduce set-up and handling time and optimize material.

We have invested $400,000 in state-of-the-art saws that are the largest in the valley, capable of cutting virtually any material from aluminum to hastelloy at any angle. The saws equipped with horizontal, vertical, and tilt heads allow us to cut angles in more than one direction to reduce set-up and handling time and optimize material.

We excel in cutting harder materials and production runs, including bundle cuts from material up to 480" long.

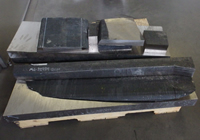

We maintain close tolerance work in a process requiring two basic methods. First, we measure the material by sighting with a laser. Then we use a computer controlled detector that prevents the blade from straying.

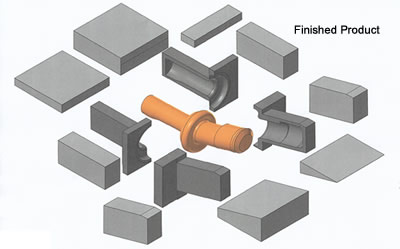

Optimizing materials to reduce waste, we are able to yield two parts from one blank.

DMSI’s inventory of machines includes an Amada VM 3800 plate saw, which has a working capacity of 10 tons to accommodate materials as large as 30” wide, 24” high, and 240” long. Using a carbide-tipped blade, the Amada VM 3800 cuts steel and a variety of other materials into segments suitable for final machining..

The Amada VM 3800 adapts to virtually any piece of material and makes cuts at any angle.

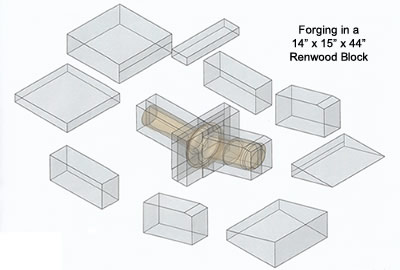

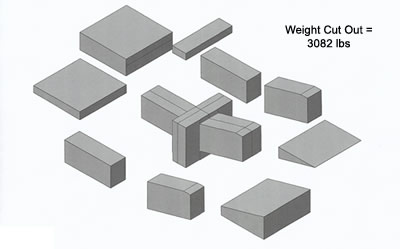

Removing excess material, which reduces machine time.

1,863 pounds of material saw cut from an Inconel forging weighing 4,020 pounds, yielding two test pieces and usable scrap instead of milled chips.

Contact us via phone, fax, or email for a quote on your next project.